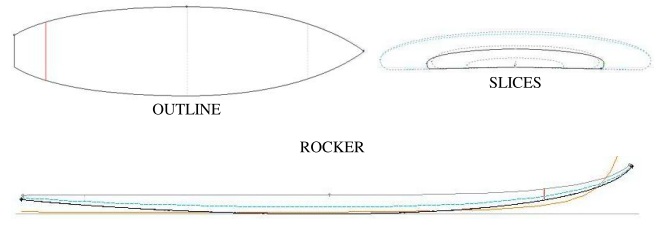

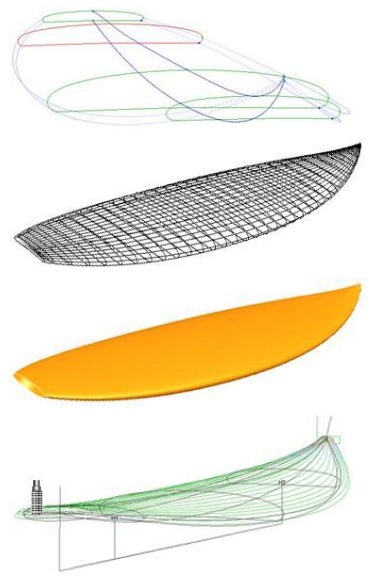

AutoSurfThe AutoSurf is a CNC machine for shaping of surfboards and stand-up boards, developed with the purpose to offer to the manufacturer of boards a product of high quality, precision, repeatability and at an affordable cost in both acquisition and operation. It is a CNC machine of three axes (X, Y, Z) for shaping and pre-formatting of surfboards and stand-up paddle boards, leaving them ready to be submitted to the finish process. The shaping is done on a blank, which is a soft foam block with wooden plywood in the central part. The function of this machine is to shape in blanks hydrodynamic profiles such as: concave, double concave, wing, edge, etc. This is done by respecting few input variables such as: length, width, Outline, Slices and Rocker.

It also has additional function for measuring the dimensions of the blank and to export them to the Shape3D, using a measuring tip and a program specially developed for this purpose.This program also allows the correct positioning of the blank to be cut on the machine. The video below shows the steps for measuring a blank of a stand-up paddle board:

The average time for cutting a surfboard is about 20 minutes and may increase or decrease proportional to the number of steps specified for cutting the board. Cutting a stand-up paddle board can be seen in the video below:

Another available accessory is a dust aspirator head that allows a cleaner cut, as shown in the video below for cutting a surfboard.

|

|

|